In recent years, our industry has witnessed a notable change in the way we go about delivering a quality-built indoor environment. Occupants now have a better understanding of the impact air quality has on their mental health and employers are starting to better appreciate the quality and productivity implications. But, why is it important that we, as building engineers, pay attention to this?

Delivering a quality indoor environment is a complex task that involves indoor air quality, minimal noise disturbance, comfortable temperature accompanied by healthy relative humidity, sensible levels of occupant density and measures aimed at protecting mental health.

All of these add up to what we now refer to as indoor environmental quality (IEQ) and illustrate just how wide the remit of building engineering specialists has become. Today, there is a lot more to our work than simply getting good quality air into a space at the right temperature.

Savings to be made

The global economic recession in 2008 led to unprecedented levels of ‘value engineering,’ all too often resulting in difficult decisions between cutting costs to meet an installation budget to providing the best solution for a building’s occupants throughout their life cycle. Yet, to those individuals, the difference between ‘price’ and ‘cost’ has never been greater. Sadly, on too many occasions we have seen our industry cross that line, with the focus and goals of a contractor under incredible commercial pressure to secure an order at the lowest possible price.

However, the World Green Building Council estimates that, on average, improving energy efficiency delivers annual savings of around 9% of operating costs to commercial building owners.

Yet, if a building contributes to staff retention, for example, – because they find it a healthy, invigorating and rewarding place to work can add up to €30 per m2, but the big winner is productivity: if improving the indoor environment results with a 10% improvement in productivity; that could be worth an impressive €300 per m2 or more.

Happiness at work is key

Keeping people happy in their places of work is, therefore, worth a lot of money. A lot more than simply reducing energy bills. That is not to say we should start ignoring energy and water efficiency. Quite the opposite. Good efficient operation is an indicator of a building’s overall quality, but if we measure our work purely in those terms, we play down our wider impact and the full potential of building engineering.

The WELL Building Standard, developed in California, is starting to take hold in Europe. A WELL Certified project has the potential to add “measurable value” in terms of the health, well-being and happiness of building occupants, according to its creator the WELL Building Institute.

Impacts on productivity

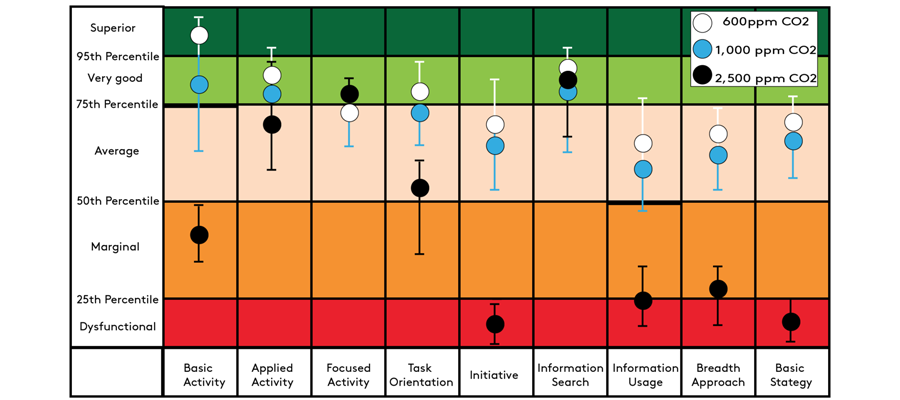

For example, on indoor air quality and ventilation the Standard argues that a well-ventilated office can double cognitive ability. For thermal comfort it has established that staff performance will fall by 6% if offices are too hot and 4% if they are too cold. Moreover, studies have found that high levels of carbon dioxide (CO2) have a significant negative impact on cognitive ability and strategic thinking as the diagram below shows.

The need to increase awareness of IEQ

Building occupants are more aware of their indoor environment these days thanks to the availability of extensive data about temperature; air quality; lighting levels etc. on smart phones and other portable devices. In the past, few people would have given much thought to the quality of an indoor environment, but due to this data, employers are starting to better appreciate the quality and productivity implications.

This makes a powerful business case for including measures for good air quality as early on in the project as possible and requires the manufacturer to help with early stage design as a properly joined up approach is the only way to achieve the best results.

The advancement in controls technology, network architecture and systems integration has allowed HVAC and other building systems to inter-operate and perform at greater efficiency levels than ever before. Though in truth, most buildings still employ only a fraction of the incredible technology currently available to help their occupants monitor and drive systems toward optimum integration and life cycle performance.

A good example within Swegon where we have embraced and are using new technology is with our ESBO tool, which allows owners and designers to select the most efficient products in a modelled space. This is a great way of capturing the manufacturer’s expertise as early as possible in the design process and should lead to the most appropriate solutions being specified.

There have been many changes over the years in this industry, but the truth is that never before have we had such an incredible opportunity to use the cutting-edge technology available to us to help improve the indoor environment in which we live, learn and work. We should embrace this chance to influence change in a way which would have a positive impact on the only true ‘value’ on which we should focus the skill of ‘engineering’ - our quality of life!

.jpg?width=75&name=0%20(1).jpg)

-4.png?width=75&name=MicrosoftTeams-image%20(3)-4.png)